# Commander series

COMMANDER Series Gantry Type CNC Automatic Vision Measurement Machine

The COMMANDER series high accuracy gantry type vision measurement machine combines high accuracy and high efficiency, offers high speed measuring for the geometric elements of different kinds of parts. The COMMANDER series is widely used in varies industries and products as PCB, copper clad laminate, pad glass, LCD modules, and insulation materials etc. Finite elements analysis is introduced in the designing process of the COMMANDER series, ensures high rigidity and accurate mechanical structure. The machine base is using closed frame movable bridge type structure, which is simple and offers high loading capability and the best motion performance. 000 grade granite machine base, offers high rigidity, corrosion resistance and high stability. The work stage is able to preset multiple products fixturing solution, also multiple lens combination is for option, satisfy different measuring requirement from different customers. Full close loop motion control system, ensures the best movement and positioning performance.

Specification

| Models | CMD862 | CMD1080 | CMD1210 | CMD1512 | CMD1812 | |

|---|---|---|---|---|---|---|

| Dimension(mm)(L x W x H) | 1700 × 1280 × 1750 | 1900 × 1480 × 1750 | 2100 × 1680 × 1750 | 2500 × 1880 × 1750 | 2700 × 1880 × 1750 | |

| Measuring Rang(mm)(X x Y x Z) | 600 × 800 × 200 | 800 × 1000 × 200 | 1000 × 1200 × 200 | 1200 × 1500 × 200 | 1200 × 1800 × 200 | |

| Measuring Accuracy (μm) | 3 + L/200 | 3 + L/200 | 3 + L/200 | 3 + L/200 | 3 + L/200 | |

| Repeatability(μm) | 3 | 3 | 4 | 4 | 4 | |

| Weight(Kg) | 1800 kg | 2900 kg | 3200 kg | 4400 kg | 4800 kg | |

| Image & Measuring | Camera | Industrial grade color CCD camera | ||||

| Lens | Manual dented zoom lens 0.7 - 4.5X / Auto zoom lens 1 - 10X | |||||

| Magnification | 18 - 195X ( For reference only. With different camera and lens the magnification will be different. ) | |||||

| Field of view | 8.1~1.3mm | |||||

| Working distance | 108mm | |||||

| Linear Scale resolution | 1µm (0.5µm for option) | |||||

| Driving System | CNC control, close-loop AC Servo driving system, joystick, mouse or keyboard control | |||||

| Illumination | Programmable 8 sections LED ring surface light, parallel LED contour light, 40 section LED ring light, co-axial light,movable multi color ring light for option | |||||

RationalVue Measuring software

Thanks to the light weight structure design, the RIDER series vision measurement machine is offering much wider application range. The RIDER series is able to be used in labs, QC rooms, even R&D center which has really limit space as a desk top precise measuring device. In the mean time, the outstanding measuring accuracy of the RIDER series makes it more adaptable to strict measuring requirement. It is a powerful measuring device for metals, electronics, 3C products, PCB or plastic industries etc.

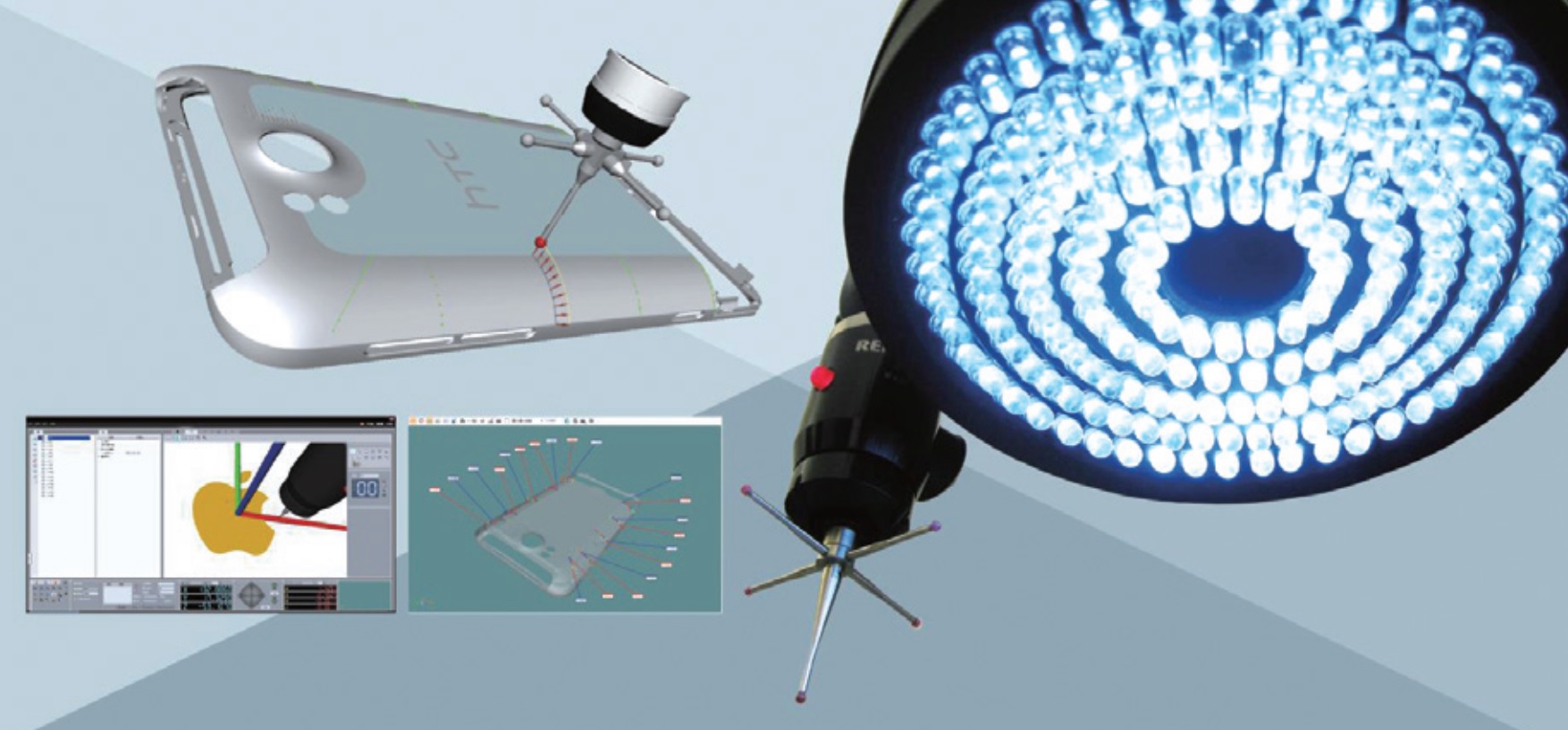

Comparison based on multiple 3D format

The software allows users to input 3D files of Iges format or CAD files of DXF format. The CAD file can be used for guiding measuring, guiding the software to do comparison between the theoretical values and the measuring results, which increases the measuring efficiency by 2-3 times. The CAD inputting allows the software to achieve ISO geometric tolerance measuring function such as position tolerance, profile tolerance for curve or curved surface.

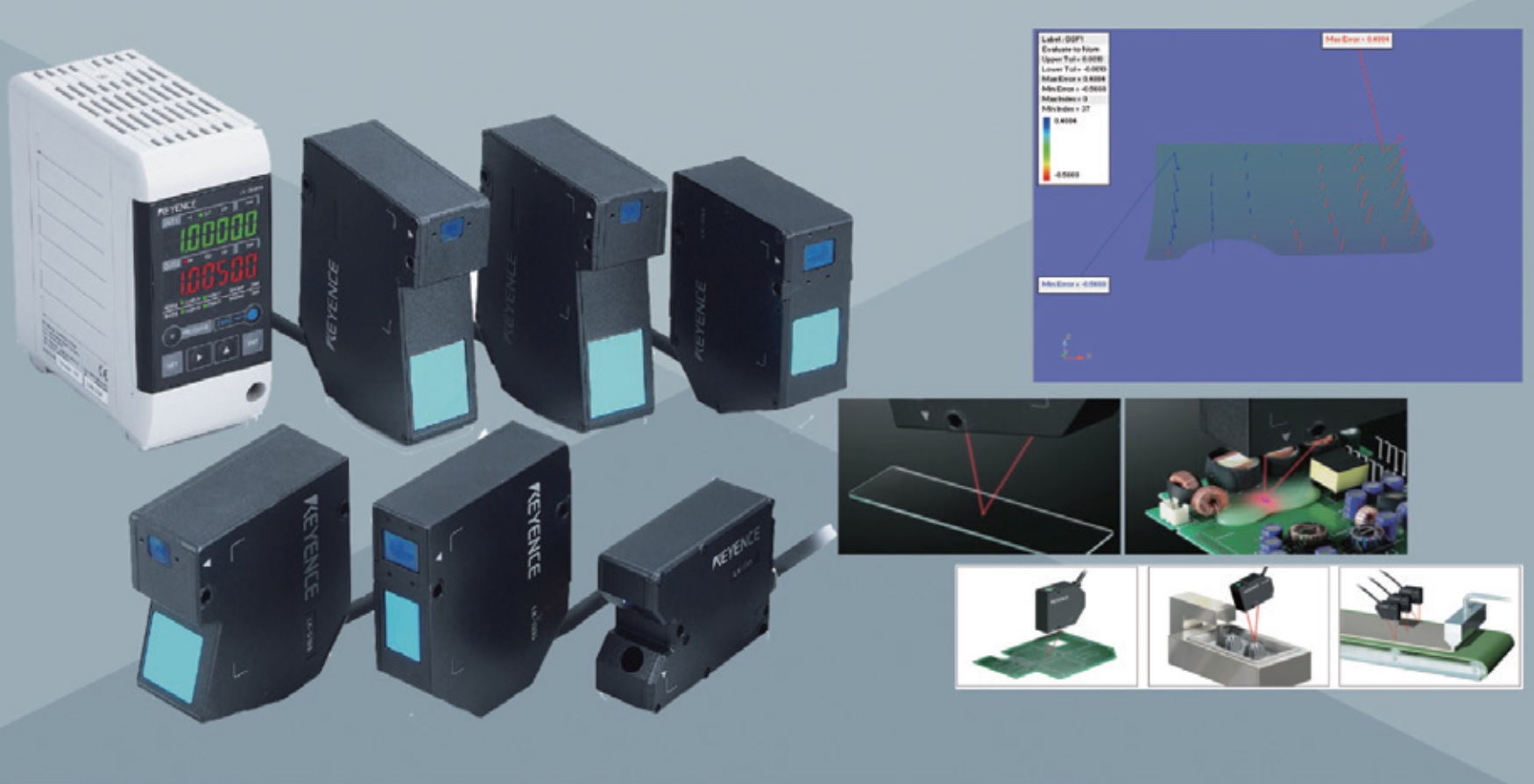

Supporting laser sensor measuring

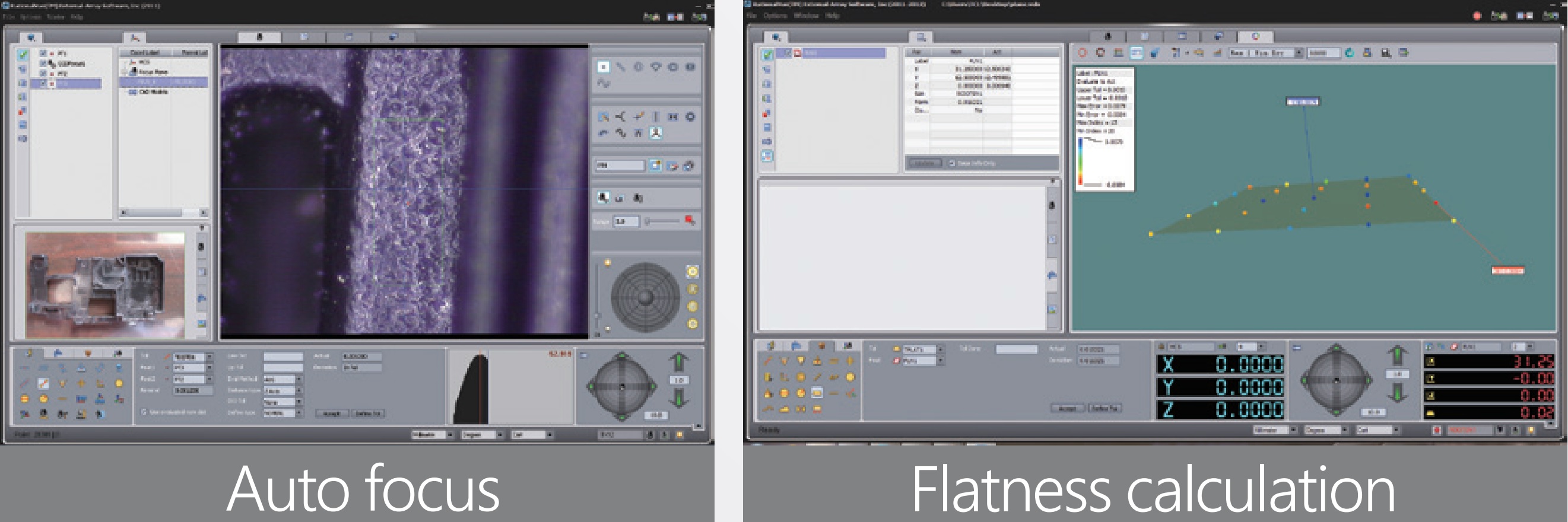

The RationalVue software is supporting the KEYENCE and Panasonic laser sensors. RationalVue is offering professional laser measuring function, allows the users to set pace and achieve non-contact measuring function automatically, complete the calculation of height, flatness and profile tolerance of the curved surface

Measure height and flatness by focusing

Thanks to the advanced focusing algorithm from RationalVue, the machine can achieve fast and precise focus operation to the parts, finish the focusing process within 2-3 seconds. The repeatability of the focusing can be up to 0.003mm, which is able to be used for measuring of height or flatness.

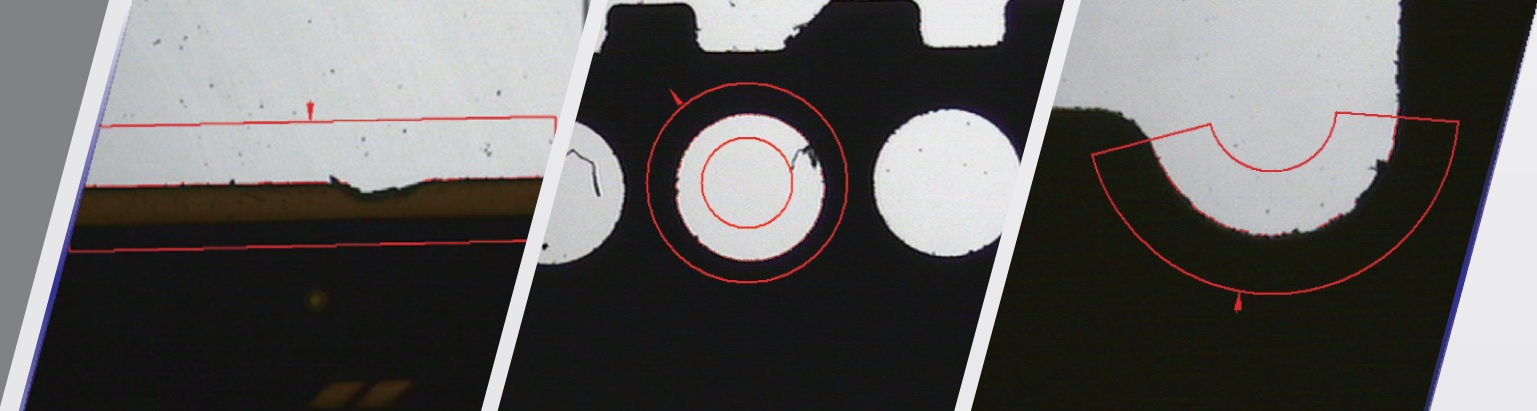

Special edge measuring

Burrs filtering

RationalVue is able to filter the burrs of the measuring parts edge,

increase the measuring accuracy. RationalVue is able to filter the

burrs of the measuring parts edge, increase the measuring accuracy